In farming, striking a balance between competing forces is key to success. This applies even to details that appear minor, including proper calibration of spray equipment and responsible, intentional application.

The end goal of any pest management application is uniform delivery of the labeled pesticide to the target to ensure good spray coverage. When calibration and application are done correctly, not only can pest control be improved but growers can also see reductions in waste of product, drift potential and less overall environmental impact, which during bloom is particularly important as growers are also striving to protect honey bee health. Growers who must spray during bloom are also highly encouraged to reference the Almond Board’s Honey Bee Best Management Practices for tips on when to spray and guidance on allowable applications during bloom.

Growers are advised to calibrate sprayers at least once a year, though the best strategy includes calibrating for early season conditions (dormancy through bloom) and again once full leaf-out occurs. Proper calibration ensures that spray rigs are ready to deliver the PCA’s recommended amount of the specified material to the trees.

Effective coverage is only possible at slow speeds. Almond Board-funded and other research shows that when proper sprayer speed, and volume, are overlooked, the result can be poor coverage, particularly in the upper portions of the trees. Studies have repeatedly shown the best coverage takes place when driving between 2.0 to 2.5 mph.

In addition to proper speed, proper volume and the distribution of material within the canopy are critical factors in providing optimum coverage and control. Simply increasing the volume of your spray is not equivalent to effective coverage.

“It’s not fairy dust; you can’t just blow it into the tree and expect it to work,” said Mel Machado, director of Member Relations at Blue Diamond Growers.

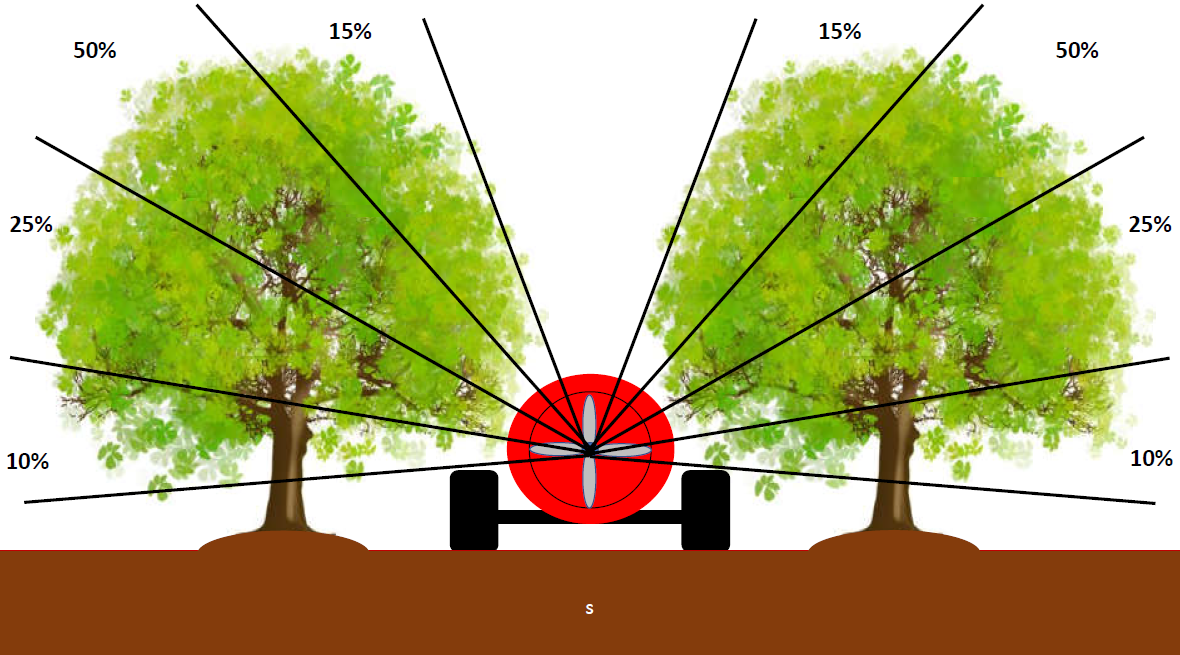

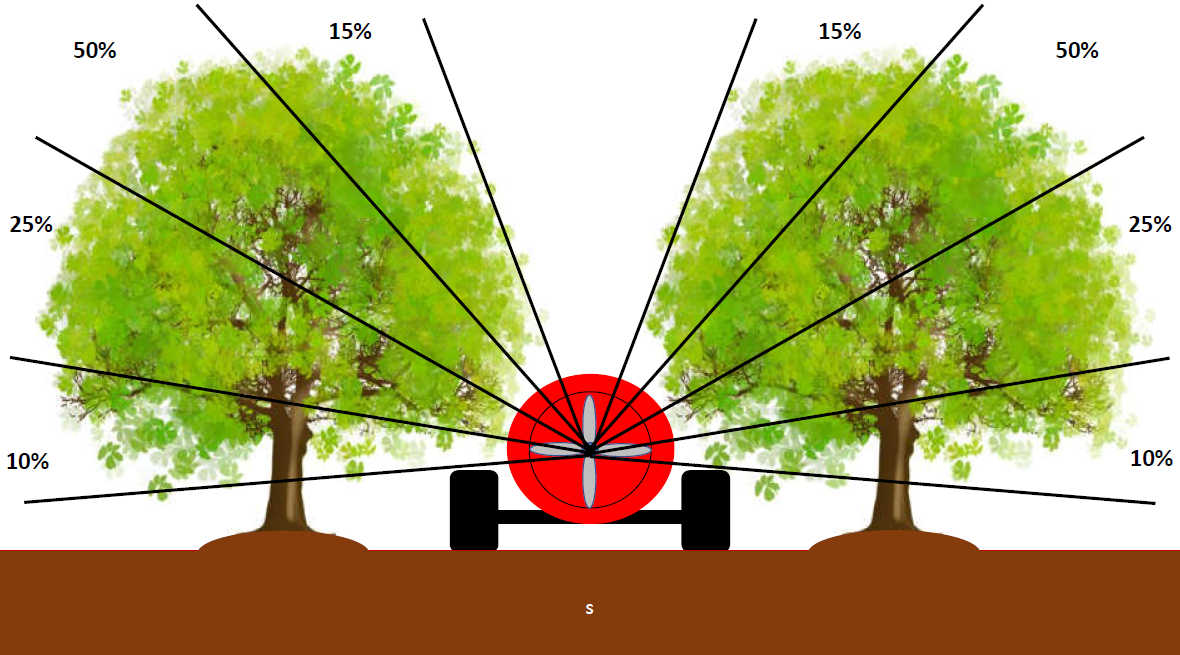

“One way to think of it is that you are working to replace the air within the tree with new air containing the spray material. The tree is a sphere. If you really look at the tree, there is greater leaf or bloom area in the center of the tree than at the top and bottom edges. If you divide the tree into quadrants, starting at the top, each quadrant should receive 15%, 50%, 25% and finally 10% of the volume, respectively. This will give you 65% coverage in the top half of the tree and 35% in the bottom half. Therefore, by default, 75% of the volume is directed to the middle of the tree. In the practical application, given the variation in height of different varieties in the same orchard, the best settings are a compromise that ensures optimum coverage,” said Machado.

In addition to the ground speed, fan or engine speed also plays a role in proper application. Growers can employ a couple tests to validate their efforts and confirm delivery to the target. One test includes using flagging tape to check for proper sprayer ground speed, the fastest speed that still delivers spray just through the tops of the tallest trees.

To employ this test, growers should position a PVC pipe with 12-18” of flagging tape tied to its end just above the top of the canopy to show if adequate airflow is reaching that point. As the sprayer drives by with the fan on, if the flag flaps out at or around 45-90 degrees, the air flow and sprayer speed is in the right range. If the flag raises to 90-180 degrees, the air flow is too fast. If the flag flutters weakly (below 25 degrees), the air flow is too low. Thus, growers should adjust their sprayer and recheck their equipment until the flagging movement is in the right range (45-90 degrees).

In another test, growers can use either water-sensitive paper, Kaolin clay or just clean water when running the sprayer through an orchard row at normal operating settings and spray flow, while ensuring to shut off or deflect any air not directed into the tree. Growers should check the coverage throughout the canopy (shown by the paper, clay, etc.) and especially focus on the hard-to-cover areas toward the tops of the trees. From there, they can adjust the ground speed and nozzle number, selection and location on the sprayer, as needed, to deliver spray uniformly through the canopy.

Growers would also do well to keep in mind this final tip from Machado: “Spraying in every other row does not work – you need to go down every row to ensure proper coverage in the orchard, especially in years with much rain and increased disease pressures.”

It's highly recommended that growers and applicators keep good records of sprayer settings and calibration for each orchard, as this will make future calibration(s) much easier.

Growers have access to multiple resources to help them navigate through equipment setup and calibration. Calibration basics are covered in the UC publication "The Safe and Effective Use of Pesticides, 3rd Edition," Publication Number 3324. PCAs, university experts and consultants from equipment companies can also provide helpful input and counsel, and the Almond Board continues to invest in research on improving spray efficacy. Looking ahead to bloom, growers and applicators are advised to reference ABC’s Honey Bee Best Management Quick Guide for Applicators for quick reminders on how best to increase in-orchard efficiency while also maintaining honey bee health.